Last Updated on June 29, 2020 by Leyla Kazim

Knorr and sustanability – what part are they playing?

We all know, and many of us love Knorr. Their stock cubes remind me of the childhood meals my parents used to cook – it’s the only stock brand they would ever use. Today, they’re in the top three chosen food brands in Europe. Globally, we’re talking 320 million people in 87 countries using their products every day. That’s big business. And with big business comes big responsibility. And keeping with the big theme, Knorr have big goals: to source all their raw agricultural ingredients sustainably by 2020.

Sustainability, what does that even mean? “It’s a blob term,” says Dr. Sally Uren, Chief Executive at Forum for the Future. These guys are a global non-profit NGO working with leading global businesses, including Unilever (Knorr is one of their brands), to address system-wide challenges, particularly in food and energy, with a mission to create a sustainable future.

There’s that word again. What Sally means by ‘blob term’, is that it’s a big and somewhat intimidating word, that can in fact be broken down into smaller and more specific conversations, which is a lot easier to digest. I like the sound of that.

Here are some scary stats: agriculture is responsible for using 70% of the planet’s fresh water, and destroying 40% of the planet’s ecosystems. Anyone can see that’s not sustainable. There it is again; the word is starting to make a bit more sense.

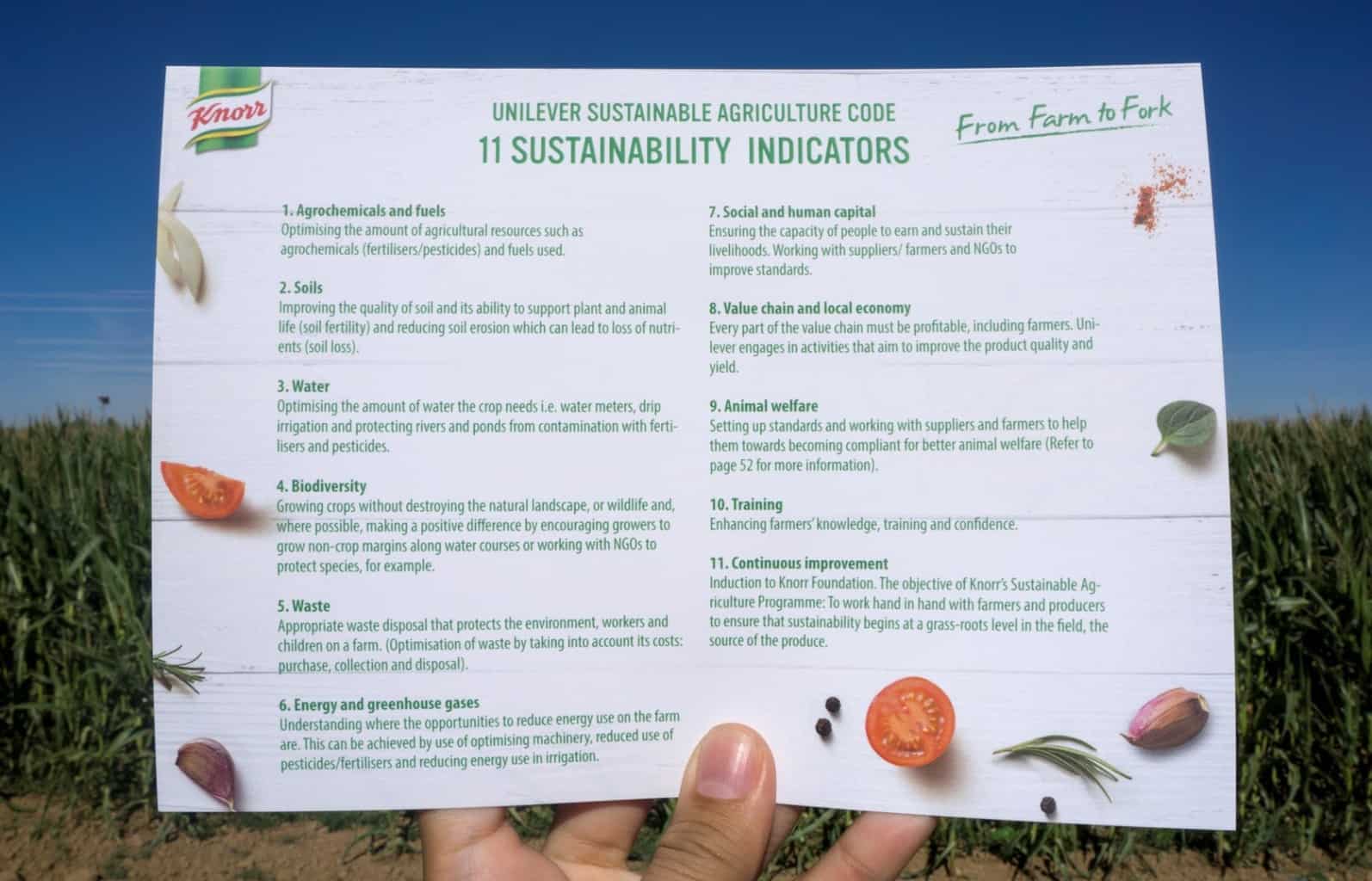

What Unilever did 16 years ago was set up their Sustainable Agriculture Programme. It’s purpose was to set a code by which farmers working with Knorr had to comply with, and continually improve upon. The handout I was given below nicely breaks down the blob term into its constituent parts, when it comes to farming:

|

| Unilever’s 11 sustainability indicators for agriculture |

So what’s been the result? As it stands, no less than 20,000 farmers are part of Knorr’s sustainable agriculture code. There are even 30 Knorr farms around the world, that have been award Landmark Farm status. This means they demonstrate the best possible standards in all this commendable stuff; they basically get a big fat gold star. And what’s particularly cool, is they open up their doors to those interested in popping by and learning about how they do it so well. The farm we visited in Badajoz – La Pinuela – is one of these. All in, 92% of the top 13 vegetables and herbs used in Knorr products today are sustainably sourced.

Knorr also estimate that operating at the current rate, in line with the holy-grail code above, around 8,258 kg of pesticides – that’s about the weight of a blue whale – will be saved from being used by 2017. Not to mention the 4,500 Olympic sized swimming pools of fresh water. And doesn’t that just make you all warm and fuzzy inside.

But it’s all very well Knorr telling people about this; the proof is in the pudding. Or the tomato. Tomato pudding? Either way, they invited me – along with a load of other journalists and bloggers from around Europe – out to Spain to see it for ourselves. We visited La Pinuela farm, the Agraz tomato factory around the corner, and ate a lot of tomatoes and great Spanish food in general.

It was a fab and informative trip, and pandered nicely to the food geek within me. Plus, I got to climb a tomato harvester. You can read about the best bits I learnt and experienced below.

|

| scenes from one of Knorr’s Landmark Farms, La Pinuela in Badajoz |

From the farm

I love a farm, me. I visited a commercial one in Andalucia a couple of years ago, growing broccoli. These parts of Spain are affectionately known as ‘Europe’s vegetable gardens’, because they produce a significant amount of the continent’s fresh produce.

Along with brocolli and tomatoes, corn is another common crop found around here. And crop rotation is key in being a sustainable farmer – it’s the best way to maintain soil fertility. Different plants suck up different nutrients; by rotating, you’re giving the ground a chance to replenish what the previous crop depleted. It makes sense, and you should apply the same principle to your veg patch.

In terms of pests, the fields were littered with traps to track their numbers, meaning pesticides are only applied when there’s a significant enough problem, rather than using it as a prevention tool from the get go.

|

| scenes from one of Knorr’s Landmark Farms, La Pinuela in Badajoz |

In high season, La Pinuela harvests 20,000 tonnes of tomatoes every day, or 150 fully loaded trucks. That’s a lot of tomatoes, from a lot of tomato plants, which need a lot of water. Right? Not necessarily. These farmers use a drip irrigation system, which gives plants just the right amount of water they need to be healthy and tasty, and nothing more. It saves 30% of water compared to just flooding the place.

And then there’s the harvester, which I scaled to get some cool tomato shots and a silly tomato selfie. The farmers thankfully turned the thing off first. Or I could have ended up as a paste myself. The machine uses a colour sorter to determine what to pick up off the ground; colours that are unlikely to ripen approaching the end of the season (so still too green), are left to be ploughed back into the field as fertiliser. Clever.

To the factory

The main ingredient in a lot of Knorr’s final products is tomato powder. You can see it in the collage below. Looks pretty unnatrual, doesn’t it. About as far from a fresh tomato as you could possibly get. Must be full of nasties to end up looking like that.

But actually, it is completely natural. Made from 100% tomato, and nothing else. This was probably the biggest revelation for me on the trip. How do they do that? It’s actually pretty obvious, by using one of the oldest preservation techniques known to man – drying.

|

| Agraz factory where tomatoes from La Pinuela are turned into paste and powder – it’s very close by |

In other words, the water is removed. The process is simple: the tomatoes are washed, peeled, de-seeded, and crushed. They’re heated up, where they’re reduced to a tomato paste. This is an end product in itself, but some of it is dried further to create tomato powder. The powder is the result of removing 96% of water from tomatoes.

Within five hours from them being picked, the tomatoes become a paste. Within six hours, they’re powder. In a similar way to freezing vegetables in the field, these lovely freshly picked fruit are frozen in time, with all the nutrients and flavour being retained by drying.

Because there is no moisture, microbes can’t grow. Which means there’s no need to add any preservatives to prolong life. It has been preserved naturally, with nothing else added.

Around 21kg of fruit is needed to make 1kg of powder, which results in the most tomato-y thing that will ever pass your lips. Check out the video below of freshly dehydrated tomato powder – cool right?

All the unwanted pulp is loaded into trucks and sent back to local farms to feed livestock, so there’s no waste. And 85% of the water used to wash the tomatoes is recycled. Even the water extracted from the juice is sent to the water station to be reused.

To the fork

All this tomato-learning and harvester-climbing is hungry work, and Knorr rewarded us duly with consistently fantastic meals. All sixty-ish of us were hosted in local restaurants, cooking us bespoke menus showcasing local produce, created by the top Knorr chefs.

There were copious amounts of cured meats, excellent cheeses, lovely salads and soups, beautiful bread, casseroles and cod, pork tenderloin and carved ox-loin, pickled pumpkin and cumin carrots, roasted vegetables and fettucini, tomatoes in every which way possible, and quite a lot of wine.

|

| getting creative in the kitchen with Knorr chefs l |

On our final day, we were invited to try our hand at coming up with our own creations, using some Knorr products such as their tomato powder and dried spices. We were put into teams and presented with a huge table, creaking under its own weight of glorious local produce, from meat and fish to fruit and veg, and we had an hour and a half to rustle something up the rest of us might want to actually eat. That’s no mean feat.

I went straight for the morcilla, pancetta and chorizo, and decided on a simple tomato-based chickpea stew, with these flavoursome meats, and the help of a friend. There were prizes to be won, and whilst I received no trophies for flavour (sob), the picture below did win me a whole leg of Spanish jamon in the food photography category. So I was pretty pleased with that.

|

| my chickpea stew with a Knorr tomato powder base, morcilla, chorizo and pancetta |

I learnt loads from this trip, both about sustainability, and Knorr as a brand. I had no idea being good to the planet and their farmers was such a big deal to them. It seems to me, when it comes to huge brands and big business, Knorr are one of the good guys.

Note: This was a sponsored trip and blog post in partnership with Knorr, in order for me to experience, learn about, and share the sustainable agricultural techniques they are pioneering, as part of their #KnorrFarmtoFork campaign. All views remain my own, as always.

Related links

10 Of the best dishes from the regions of Murcia and Andalusia